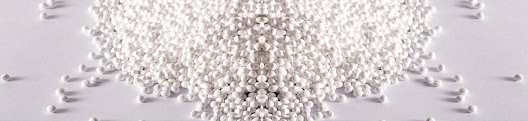

Facts About Colour Masterbatches

Colour masterbatches are

widely used for colouring purposes, like the colouring of plastics and their

dyes. Colour masterbatches are made through a process of heating strategy in

which a resin is added and fir cooling converts it into a granular form. Colour

masterbatches are helpful in the manufacturing of plastics by making them more

genuine, useful, and vibrant.

There are masterbatch

manufacturers in India whose masterbatches have

these amazing aspects of use and function:

- They are used in the administrative norms, which are

colourful.

- They are fashionable and have great performance across

industries and applications of plastics.

- They are economical.

- They are supplied to various industries.

- Some manufacturers make multi-technology systems of

masterbatches that are white, filler, and additive masterbatches.

- Masterbatches of high quality are mainly used for

extrusion, moulding, and compounding.

- Polymer colour masterbatches are used for interior and

exterior purposes for products in the plastic industry.

- Colour masterbatches are widely used in the market for

plastic packaging of food, toys, cosmetics, electronic goods, medical

equipment, automotive interiors, and even artificial grass.

- used for heavy engineering are used for demanding

applications.

- They are also available in a huge range.

- They are used for film and sheet extrusion, pipe

extrusion, etc.

- The colour masterbatch is very accurate and of high

quality.

The

benefits of masterbatches as provided by the masterbatch manufacturers in India

are:

- The needs of the customer are met as there is a wide

choice of colours.

- The processing of the colour masterbatch is consistent.

- good colour performance in extreme conditions.

- perfect finish and fewer defects.

- low energy costs.

- good output and low production costs.

- Proper technical support and expertise

Comments

Post a Comment